Welcome to visit Luoyang Bolin Intelligent Equipment Co., Ltd!

Product Series

Contact Information

Address: Donghu Garden Section, Luoyue Road, Lilou Town, Luolong District, Luoyang City

Telephone:+86 0379-65950588

Whatsapp:+86 18637907768

Zip Code: 471000

E-mail:luoyangbolin@126.com

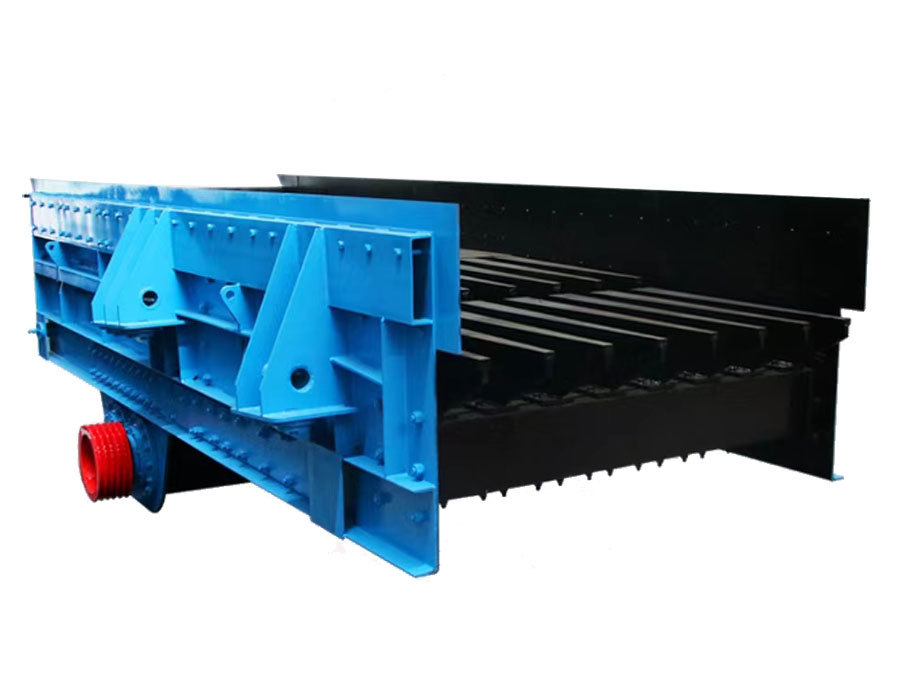

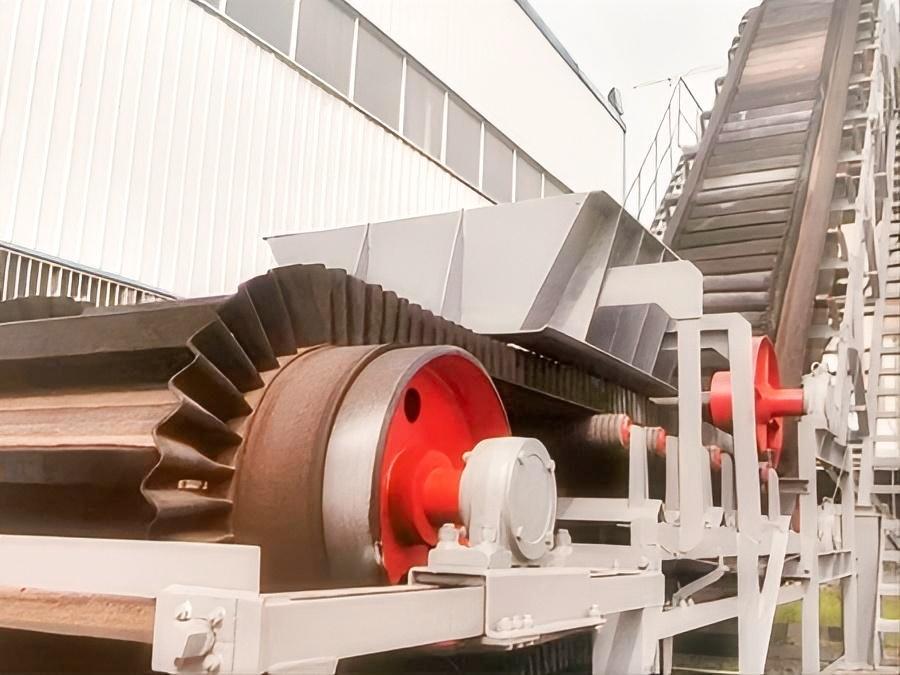

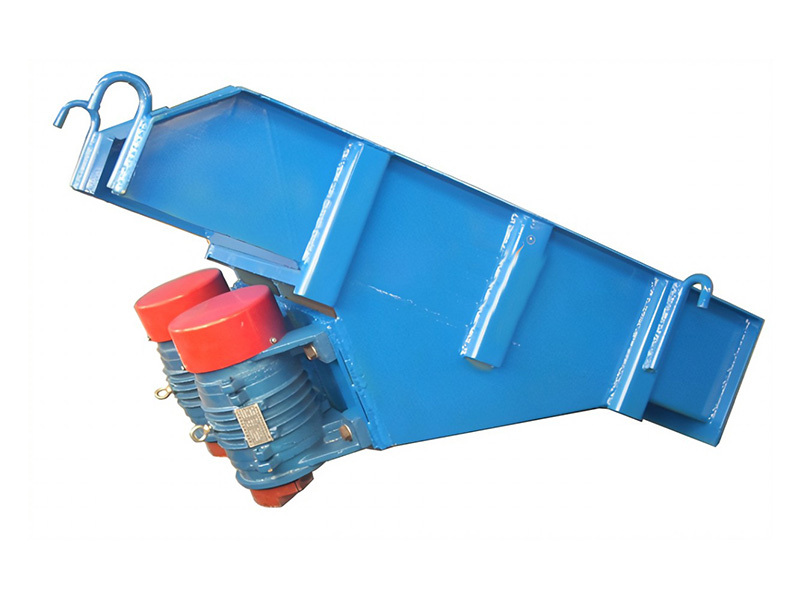

Plate feeder

Purpose and scope of use

The medium-sized plate feeder is designed and manufactured according to the JB225-86 "Medium-sized plate feeder". It is suitable for horizontal or inclined conveying lines, and continuously conveying block materials from the storage bin to the crusher, conveyor or other working machinery. The bulk density of materials is not more than 2400 kg/m, the block weight is not more than 500Kg, the temperature is ≤ 400 ℃, and the inclination angle is ≤ 25.

This product is widely used in mining, quarrying, metallurgy and cement enterprises. It is an indispensable equipment in raw material processing or continuous production process in the process of crushing, transporting and batching. It is especially suitable for transporting large, high temperature and sharp materials, and can work reliably in harsh environments such as open air and humidity.

Performance and structural characteristics

1. The driving device adopts vertical axis, hard tooth surface cylindrical gear reducer and electrical protection device, which has the characteristics of uniform speed regulation and automatic overload protection.

2. Large feeder adopts limited rectangular hydraulic coupling, which has the function of mechanical overload protection.

3. Sleeve roller conveyor chain is designed and manufactured according to ISO1977/1-1976. The surface of the roller is carburized and quenched, and the wear resistance is good.

4. The sprocket is made of cast steel and alloy cast steel, and the tooth surface is hardened, with good wear resistance and long service life.

5. All the rolling bearing support structure, good sealing and lubrication performance, low running resistance, easy to repair and maintenance.

6. The frame of the truss structure has light weight, good rigidity, small footprint, easy adjustment, assembly and disassembly and transportation.

7. The whole machine adopts a fully enclosed protective cover, which is conducive to dust discharge and environmental protection.

8. For the inclined installation of the feeder, the reverse of the automatic back running mechanism is adopted.

Feeder structure type

P-type-the longitudinal section of the bearing plate is flat plate type, suitable for conveying massive materials along the horizontal or inclination ≤ 15 °.

L type-the longitudinal section of the bearing plate is wave type, suitable for conveying block or granular materials along the horizontal or inclination ≤ 25 °.

H type-the longitudinal section of the carrier plate is circular arc type, suitable for conveying wet and viscous materials along the horizontal or inclination ≤ 25 °.

Key words:

Plate feeder

Related Products

Contact Information

Address: Donghu Garden Section, Luoyue Road, Lilou Town, Luolong District, Luoyang City

WhatsApp:+86 18637907768

Zip Code: 471000

Product classification

Douyin Official Media

Quick Hand Official Media

WeChat Public Number

Add WeChat

Get your industry solutions fast!

We will contact you within one working day. Please pay attention to your email.

Copyright©Luoyang Bolin Intelligent Equipment Co., Ltd. has supported ipv6